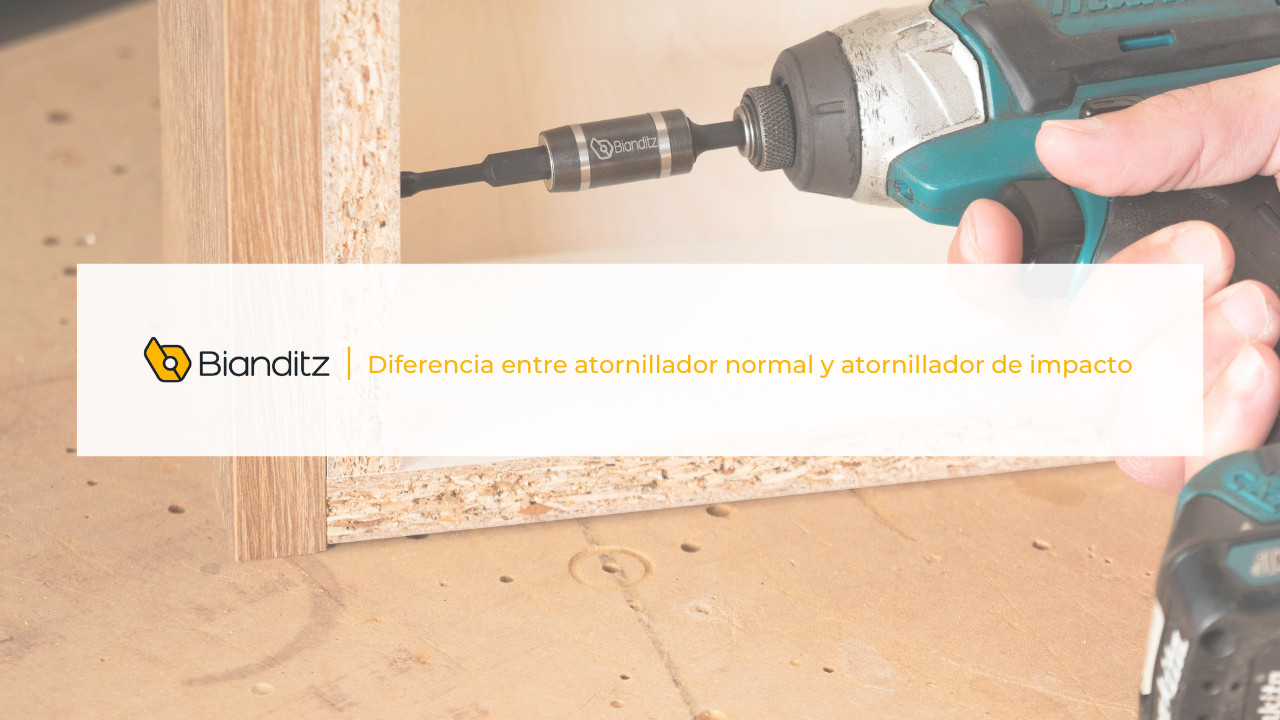

difference between normal screwdriver and impact screwdriver

If you are one of those people who like to make small reforms at home or you are a professional who is dedicated to a trade related to construction, more than once you have had to use a screwdriver or impact screwdriver to perform your task correctly. Now, do you know the difference between the normal screwdriver and the impact screwdriver? If you don’t know, we will explain below the differences between both screwdrivers and we will also give you a little advice on which are the recommended bits for each type of screwdriver.

What is a normal screwdriver

A screwdriver or screwdriver (term by which it is known in Latin America) is a tool that is used to tighten screws mostly, but we can also use it to loosen, in most cases. Until a few years ago, most screwdrivers were used manually, but more and more we tend to use electric screwdrivers. These screwdrivers adapt to all types of 1/4” bits, so we will have great flexibility when performing different jobs using PH, PZ, Plana, TX bits… The basic electric screwdriver does not have any type of hammer or impact, so it is used in places where the torque required is not very large, furniture assembly or places where there is no need to tighten the screwdriver, or in places where there is no need to tighten the screwdriver.What is an impact driver

Impact drivers have the same function as a normal screwdriver, but their use is more professional than the normal screwdriver. The impact screwdrivers have a kind of striker that produces a torque peaks on the screw generating up to 100Nm. This type of screwdrivers will be used when we want to put a lag screw in a surface where we need a higher torque, it can be in hard wood, walls, floors… The noise generated by the impact screwdriver is very characteristic because when it requires a higher torque stops rotating regularly and begins to rotate with small strokes.What is a hammer drill and screwdriver?

A screwdriver drill is a very versatile tool that can be used both for screwing on surfaces that do not require high torque and for drilling holes with drill bits in different places. The peculiarity of this tool is that it produces an impact on the drill bit when making holes in hard surfaces such as a wall and thus the hole is made in an easier way. The hammer driver will be used in hammer mode to make the previous hole while we will use the screwdriver position when we are inserting the lag screw. If we see that the torque produced by the drill is not enough when screwing, we will have to resort to an impact screwdriver.Difference between normal screwdriver and impact screwdriver

While the impact drill produces the impact on the screw head, the impact screwdriver generates this force in a clockwise or counterclockwise direction (depending on whether we are screwing or unscrewing). So the difference between the normal screwdriver and the impact screwdriver is in the way in which the impact is generated. That is why, if we are going to put a lag screw in a surface where we do not need a large torque, we will be able to do it with a normal screwdriver as well as with the basic electric screwdriver, while if we are going to need a higher torque it is advisable to use an impact screwdriver.