PRECISIÓN PARA INYECCIÓN Y CORTE

⁄MOLDS AND CUTTING

DIES

projects

projects

We carry out more than 80 projects per year

People

People

A great team of 28 individuals

Resources

Resources

Over 18 production facilities

area

area

Large facilities

60 years

⁄We are

manufacturers of rubber molds and cutting dies since 1965

At Bianditz Molds and Cutting Dies

We are manufacturers of rubber injection molds, compression molds, rubber-metal molds, and combined cutting and bending dies.

SERVICES

/Flexibility and

reliability for robust

and durable finishes

INJECTION MOLDS, COMPRESSION MOLDS, AND RUBBER-METAL MOLDS

Design, construction, and subsequent maintenance of molds for rubber: Injection, injection-compression, compression, and rubber-metal. For use in both vertical and horizontal presses.

Molds with single plates, intermediate plates, part ejection plates, and with core carrier frames (cores). Regulated channel blocks BCR.

Maximum dimensions of molds 1,200 x 2,000 mm.

COMBINED CUTTING AND FOLDING / BENDING DIE

Design, construction, and subsequent maintenance of dies for cutting, punching, and folding. Single, compound, and progressive dies.

Maximum dimensions of the dies: 1,200 x 2,000 mm.

Since 1965

Technical means of

production

001

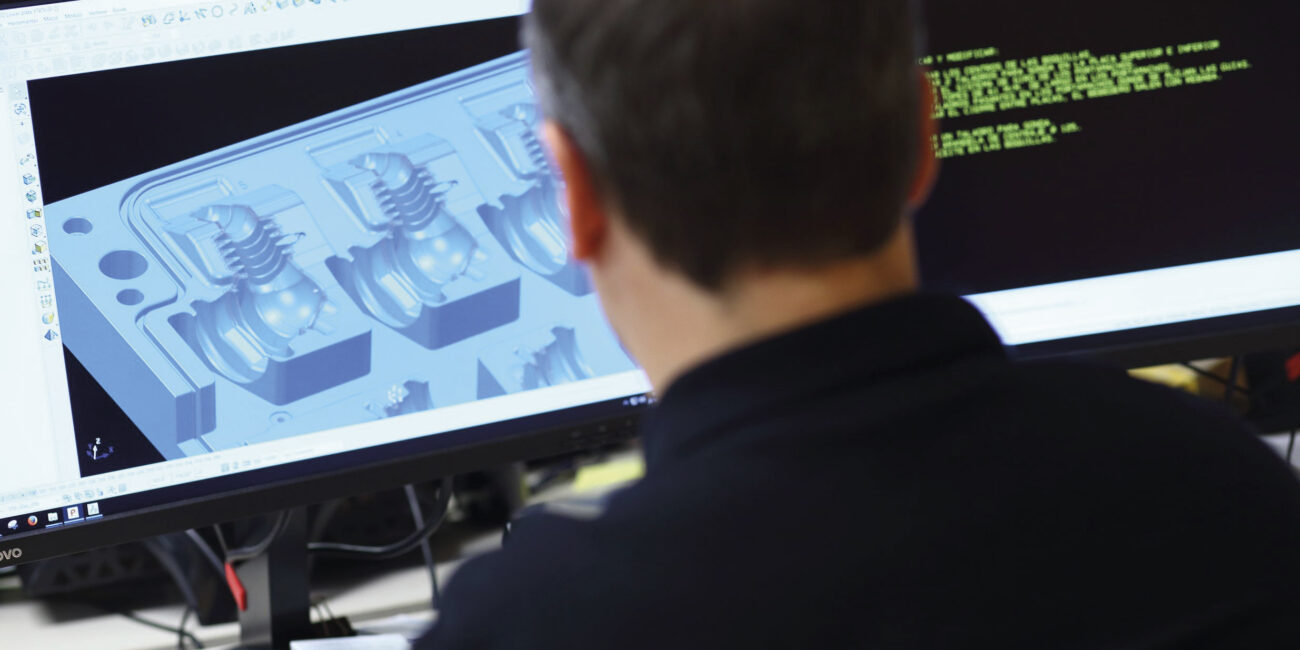

Machining centre: We have 6 precision vertical machining centers with maximum work capacities on plates of 1,200 x 2,000 mm, and machining capability of up to 60,000 rpm for extra-fine finishes.

machining centers

002

Two wire-cutting machines with a travel of 400×600 mm each. Two sinker EDM (Electrical Discharge Machining) machines with a travel of 400×600 mm each.

Wire and penetration EDM

003

Various auxiliary machinery in a metalworking company: Grinders, polygonal profilers, vertical drills, thread cutting machines, TIG welding, cold welding, Vision Engineering & Quadracheck profile measuring device, laser marking, etc.

Auxiliary machinery

004

We collaborate with other approved / authorised suppliers, offering comprehensive or surface heat treatments, chemical or electrolytic coatings / recoverings, laser engraving, and reverse engineering, among other services.

Other partnerships / collaborations

005

Delcam PowerSHAPE, SolidWorks, Delcam PowerMILL, Fanuc CAMi

CD-CAM design and programming

CUSTOMERS WHO TRUST US

REAL CASES

Cutting Dies for industrial lines | Testimonial: DIMECO

DIMECO: Who are they? In Dimeco They specialise in punching and profiling lines for the industrialised manufacture of metal parts. ‘At

We celebrated our 60th anniversary with a moving gathering.

More than 80 people, including employees, customers and partners, took part in a day that served to review the company’s history and look towards the future. Last Friday,